Recycling heirloom stones and gold

At Susan Ewington Jewellery, we value and appreciate working with heirloom gemstones and elements from pieces that may be past being repaired or for sentimental reasons. Not only does this enhance the story of your piece of jewellery, but it also allows for our continued commitment to keeping things greener.

However, not all components in old jewellery can be used easily or effectively. There’s a reason not all jewellers offer this service as it can be fraught with risks and frustrations! So it’s really important to know that even the best intentions can go awry.

Because we also value transparency and education, here's our best tips and things to know about the possibilities of reusing Nan’s ring, Dad’s wedding band, or anything else you might be interested in recycling into something new (and that you’ll actually want to wear instead of it being stuck in a draw!)

Recycling Gemstones

What are some of the main risks involved?

Stones may get scratched or crack when being removed from their settings (yes, even diamonds!)

Sometimes a customer thinks or have been told that they have a particular stone type, but turns out it is something else once we start working with it.

Some stones may have been highly treated (such as resin filling or fracture filling in low grade rubies) and therefore may not respond well to being re-used.

What happens to broken stones and leftover stones?

Any un-used gemstones (that are intact but not necessarily right for the new design) will be boxed and returned to you. You can use these in future projects or to pass on to a loved one to use instead.

A broken gemstone might be able to be re-faceted by an expert gem cutter so that it looks complete and practically brand new. It may be ever so slightly smaller than the original shape, but it will still hold all the sentiment of the original stone. Only larger sized gemstones can be re-cut, not the teeny tiny ones.

Teeny tiny gems that are broken can not really be re-used, and it will be up to you whether you’d like to hold onto them or not, but they can rarely be re-set into a new piece.

Recycling Precious Metals

How do we recycle it in the studio?

Pieces get assessed and tested for carat purity by Susan before any stones are cut out or pieces pulled apart.

Metals that have been approved for re-using are then divided up into components for melting. For example, solder seams are removed, white metals are separated from yellow metals, or stones are cut out.

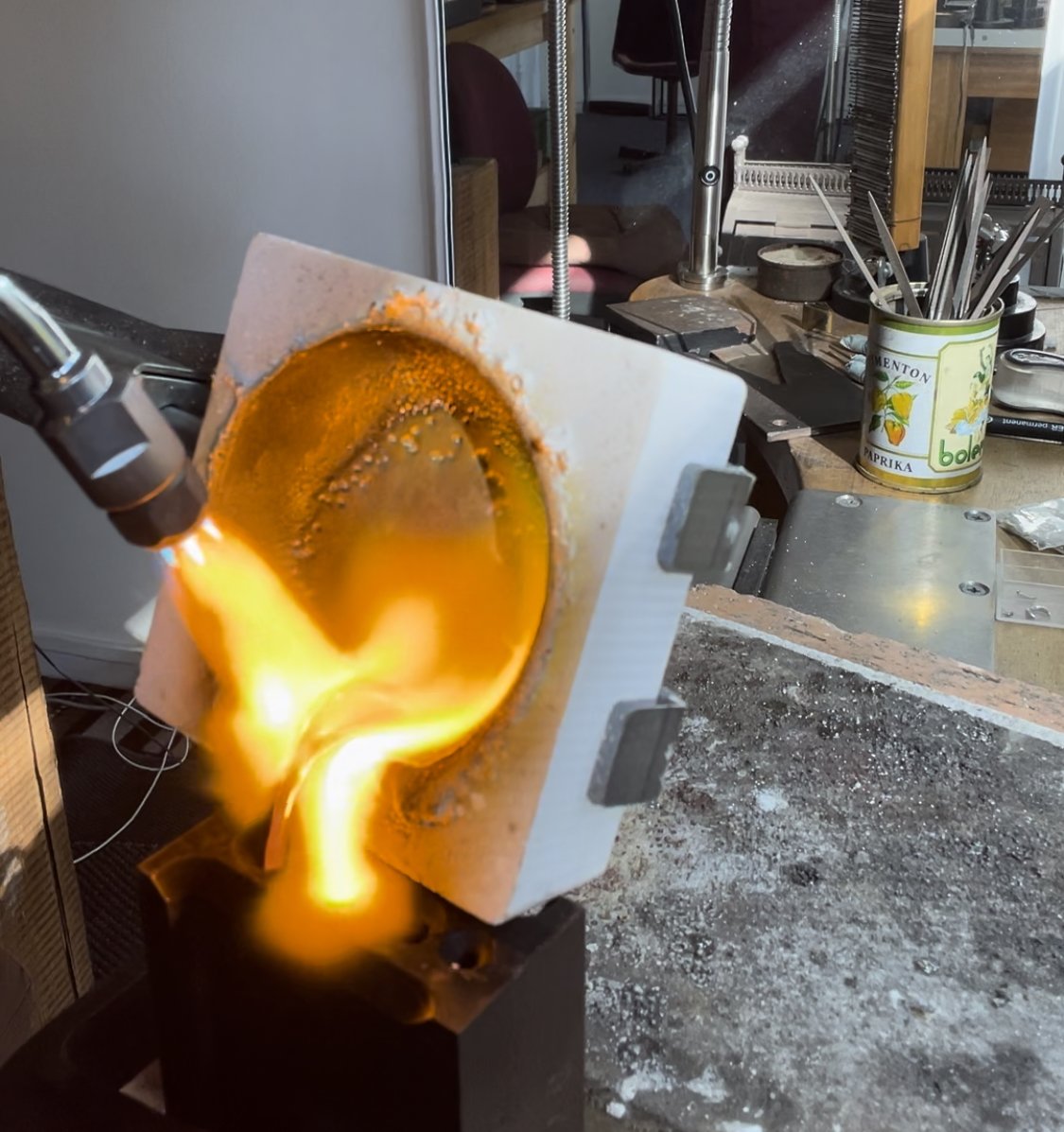

All the metal that is being recycled into a new piece can then be prepared for melting. This process is called 'making an ingot’. The new ingot is what’s used for making the new piece of jewellery.

Sometimes gold may be wrongly hallmarked (the purity of the gold), of poor quality alloy (the recipe of the gold) and not re-melt well enough to be used again. In these instances, fresh metal may need to be added or used completely for the new piece.

What happens to unused or unusable metals?

See the chart below for the most common ways the different metals can be recycled in the studio.

Metals that can’t be re-used in house are weighed and valued as ‘scrap’ which can be credited to your final balance owing on the new piece. The ‘scrap’ is sent to a local Sunshine Coast refining company who extract the pure precious metals out of it and this gets returned to the precious alloy industry to make into new alloys. This is the cyclical nature of the precious metal industry, and absolutely no precious metals go to waste!

Sometimes the ingot may not be ‘behaving’ when it’s being made into the new piece of jewellery. In this instance, Susan will be in touch with a Plan B to use fresh , and that unusable ingot will be valued as scrap and go through the credit and refining process explained in the above point.

If we are using your recycled gold for your new piece, and there is excess scrap left over, this can either be returned to you or weighed and valued as scrap to credit your balance owing. This only includes whole scrap pieces, not the filings and dust that occurs during the making process.

The filings and dust created during the making process is called ‘lemel’ and this is eventually recycled through the refining process. In the workshop, we collect all lemel, vacuum dust, sweepings, and any other dust that accumulates in the workshop so that it can eventually be refined to extract the traces of precious metal so it does not go to waste.